ASME Coded Vessels

With the help of our on-location post-weld heat treatment (PWHT) furnace, Twin Brothers builds pressure vessels in accordance to ASME Code standards. As an ASME pressure vessel manufacturer, we continue to meet industry and legal safety standards. Our vessels are sized and shaped to meet design standards, manufactured from approved materials, fabricated using approved techniques, and further examined and inspected upon completion.

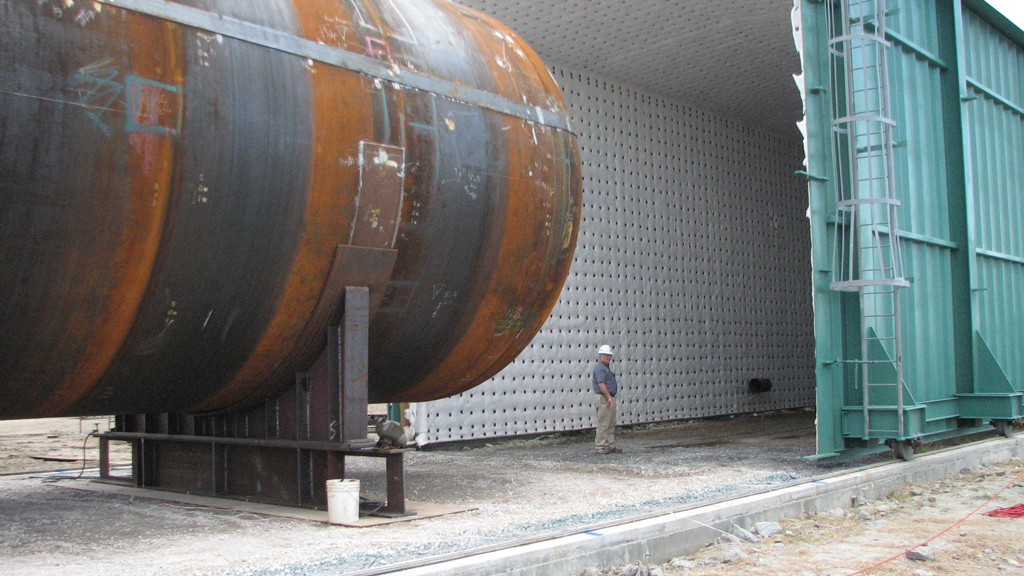

POST-WELD HEAT TREATMENT

Twin Brothers’ facility boasts a custom designed post-weld heat treatment (PWHT) furnace that can treat pieces up to 115 feet in length. This furnace, located at our Port of West St. Mary location, is one of the largest in the country and a huge time-saver for customers … which translates to a huge cost saver for customers!

Used for the post-weld heat treatment of pressure vessels built in accordance to ASME Code standards, among other vessel pieces, the outside dimensions of the furnace are 26’ W x 27’ H x 120’ L. Parts can be heat treated at a temperature range of up to 1700°F, with a temperature uniformity of +/- 40°F during the heating cycle. The PWHT processes ramp up and down, depending on customer heating and cooling rate specifications. With a total of six ratio/fixed air furnace burners (10 million BTUs each), the post-weld heat treatment furnace provides a safe, reliable, efficient and clean heating process using raw propane.

Twin Brothers’ furnace is also used to PWHT others structures that require this process such as bridge girders, drilling rig components, structural pipe, etc.